-

WhatsApp: 8613816774633

-

email: export@polycmill.com

Solvent & Water Based Paint Production Line for Ecudor Customer

May 05, 2025

Wall Putty Production Line for Ecuador Customer

Project name: Solvent & Water based paint Production Line

Project time: Dec.2024

Project installation country: Ecuador

Customer’s material information:

For Solvent & Water based paint

Material Density [kg/m3] 1400

Viscosity [mPas]:4000-20,000

Solids:70-80%

Production capacity:15-20Ton per day

Customer’s requirement: The customer’s paint used for out wall no need grinding system. They just need pre-dispersing kettle and finished product storage kettle with low speed agitator. In recent year the labor cost and energy cost in local is higher so the customer need we offer the high working efficiency pre-mixing system and energy saving low speed agitator.

POLYC solution:

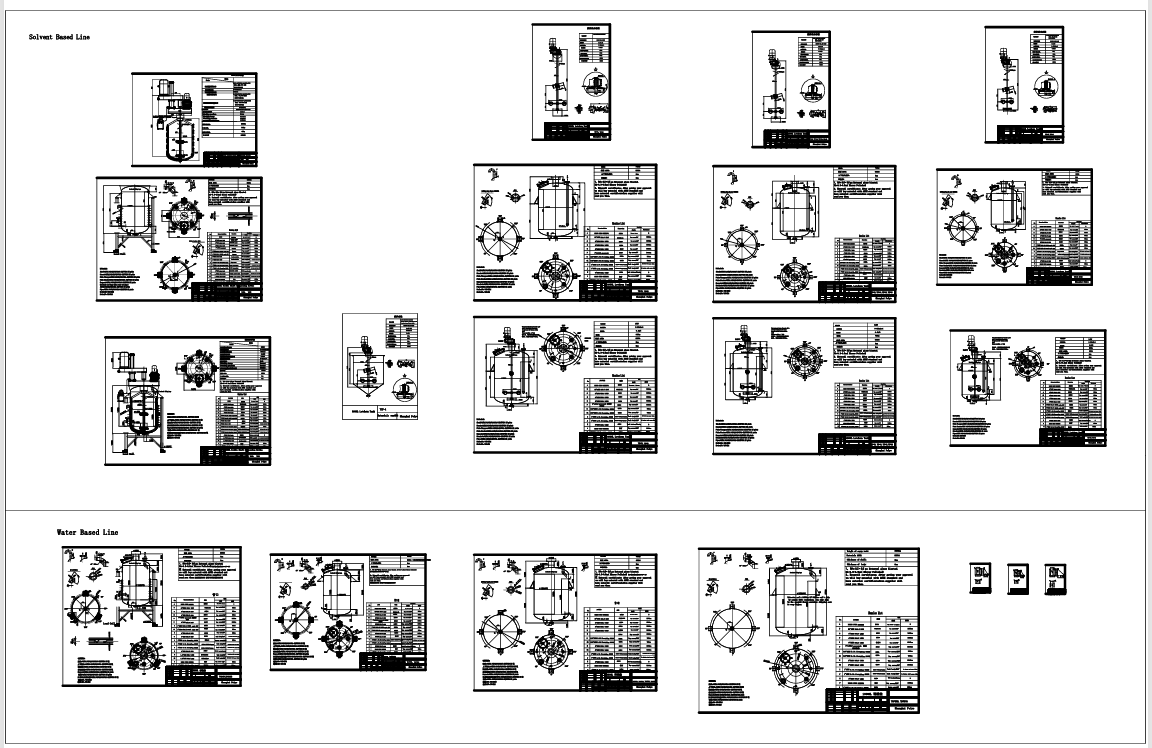

(Technical drawing of the production machine)

1.Pre-dispersing system:We equip Concentric Double Shaft Mixing Kettle (One high speed shaft +one low speed anchor mixing shaft) as the material solid content is high 70-80% this structure of mixing kettle is best suitable, the kettle outside with half coil for cooling better control temperature of material during mixing. The high speed dispersing shaft with hydraulic lifting system can lift up the down make sure even and thoroughly mixing.

2.Finished product storage kettle with low speed agitator.We equip with cup type mixing blade. Unlike traditional paddle type mixing shafts it’s working efficiency higher, energy saving and also has following advantages:

-

- High circulation performance

- Slotted version, more stream angles shearing power

- Strong suction effect in the ground area

- Strong wall flow

- Very good intake performance

- Circumferential speed up to 4m/s (smooth stirring, no air intake)

- There is no bubble, no dead corner and no scale. lt is suitable for mixing with medium and low viscosity. Can reduce the damage to the molecular structure of the solution during the mixing process, reduce the dispersion, and make the mixing more uniform.

Customer inspection before shipment:

Shipment time:

March.2025 We successfully arrange shipment for this projected totally 7pcs 40HQ were loaded

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Apr 28, 2025

Wall Putty Production Line of Argentine Customer

Sep 06, 2024

1000L Basket Mill For Pigment

Aug 20, 2024

500L Electrical Heating Reactor

Oct 20, 2023

SC formulation in China![loading... [120x35]](https://shopsource.singoo.cc/1750/general/WQj5wtRMSZiW52yR/078e2d1bd48e42f9ab387ca9dc421b4_1913.png?x-oss-process=image/resize)